Temperature Monitoring

Importance of Temperature Monitoring for Fridges and Freezers:

- Food Safety:

- Ensures perishable foods are stored at appropriate temperatures, preventing bacterial growth and foodborne illnesses.

- Maintains the integrity of frozen foods, preventing freezer burn and preserving texture and taste.

- Medicinal Integrity:

- Pharmaceuticals and vaccines often require specific temperature ranges. Monitoring ensures these products remain potent and effective.

- Biomedical samples and research materials are preserved accurately for experimentation and analysis.

- Compliance:

- Regulatory bodies often mandate specific temperature ranges for storing certain products. Monitoring helps businesses adhere to these guidelines, avoiding legal issues.

- Quality Preservation:

- Proper temperatures preserve the quality, taste, and nutritional value of stored food items, ensuring customers receive high-quality products.

- In pharmaceuticals, maintaining the right temperature ensures the efficacy of medicines, preventing financial losses and ensuring patient safety.

Effective Implementation of Temperature Monitoring Systems:

- Continuous Monitoring:

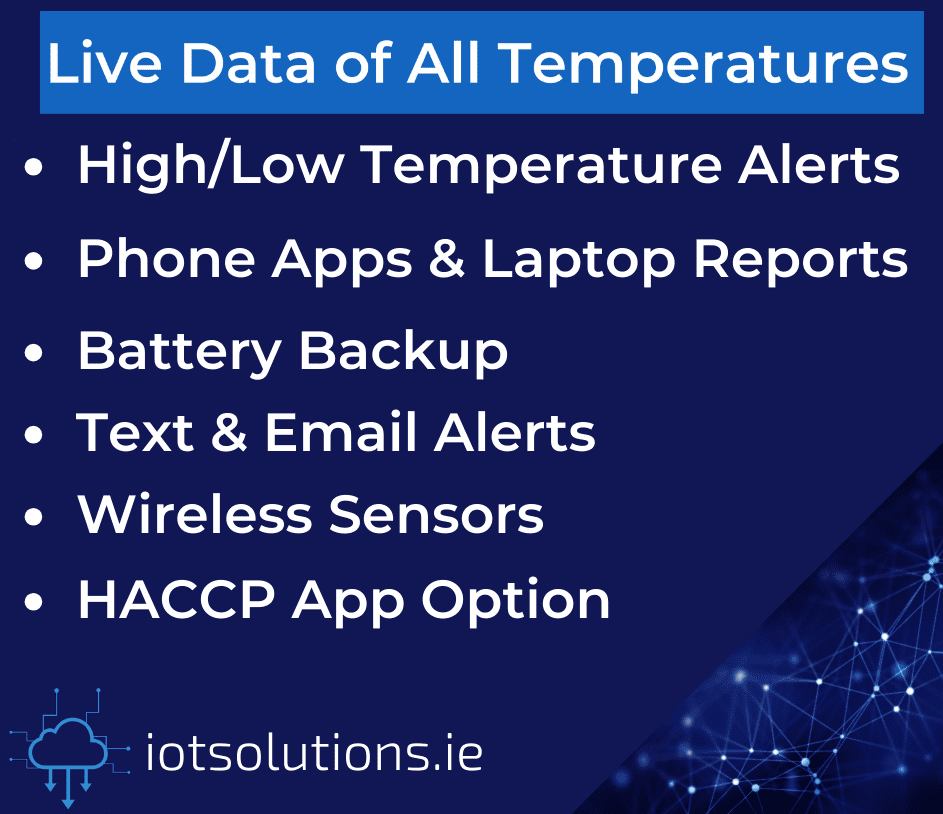

- Utilize digital temperature monitoring devices that provide real-time data. These devices can be set to trigger alarms if temperatures deviate from the desired range.

- Implement sensors within the fridge and freezer to monitor different zones and ensure uniform cooling.

- Remote Monitoring:

- Invest in systems that allow remote monitoring of fridge and freezer temperatures. This is particularly useful for businesses with multiple locations.

- Remote monitoring enables instant alerts and notifications via email or SMS, allowing for swift action in case of temperature fluctuations.

- Data Logging and Analysis:

- Implement data logging systems that record temperature data over time. This historical data is valuable for analysis, trend identification, and compliance reporting.

- Analyze temperature data to identify patterns and make informed decisions about equipment performance and energy efficiency.

- Backup Power Systems:

- Install backup power systems like generators or uninterruptible power supplies (UPS) to ensure continuous operation during power outages. Temperature monitoring should continue even during electrical failures.

- Regular Maintenance:

- Conduct regular maintenance checks on fridges and freezers to ensure they are functioning correctly.

- Calibrate temperature sensors periodically to maintain accuracy in readings.

- Training and Protocols:

- Train staff to handle temperature-sensitive products properly. Implement protocols for opening fridge and freezer doors, ensuring they are not left ajar for extended periods.

- Have clear procedures for what to do in case of a temperature excursion, including steps for moving products to backup storage if necessary.

- Documentation and Compliance:

- Maintain detailed records of temperature data, including timestamps and any corrective actions taken.

- Regularly review and update protocols to ensure they align with the latest regulations and best practices.

Implementing robust temperature monitoring systems for fridges and freezers not only ensures compliance but also safeguards the quality and safety of stored products, thus enhancing customer satisfaction and the reputation of your business.